10 Jul Why Do You Need Total Precision Engineering?

Posted at 11:42h

in Blog

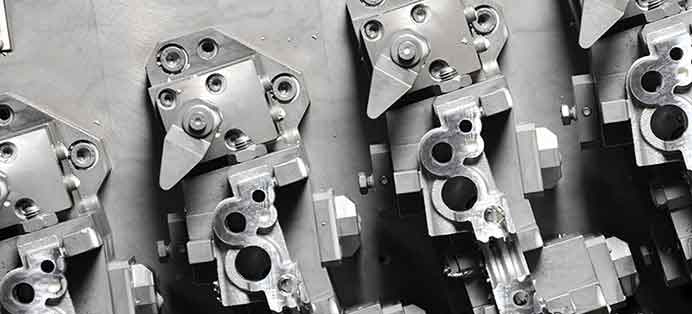

Precision engineering allows you to reduce cost and improve your product performance in a creative yet efficient way. By optimising manufacturing techniques and improving functionality, working with Italy Precision CNC Machining can improve reliability, performance and the total cost of ownership without compromising on quality.

- Simplicity- By adopting a one-stop solution, total precision engineering simplifies what can be a complex process, all tasks from machining to laser marking can be undertaken by one supplier in one place.

- Lower costs- Everybody loves a bargain. Total precision engineering can produce specialised parts whilst reducing waste and speeding up production. However, using a single supplier is crucial, allowing economies of scale to come into play and reducing the cost per part.

- Part optimisation – gives you a competitive edge in the market. By being allowed to make changes, it allows the supplier or engineer to strengthen the project, whether it be through components or designs. This allows the end product to become more cutting edge and efficient for the customer.

- Secondary production operations- By using one manufacturing technique, the engineering process becomes much simpler. Here at Italy Precision CNC Machining, we use cold-forming. Cold-forming eliminates unnecessary processes whilst reducing waste, total costs of up to 70% and improved mechanical strength.

Read more about total precision engineering and how we can support you here.